FSN E-commerce Ventures Ltd. (FSNEV) popularly known as “Nykaa” is a digitally native consumer technology platform, delivering a content-led, lifestyle retail experience to consumers. The company has a diverse portfolio of beauty, personal care, and fashion products, including owned brand products manufactured by it.

Financial Results:

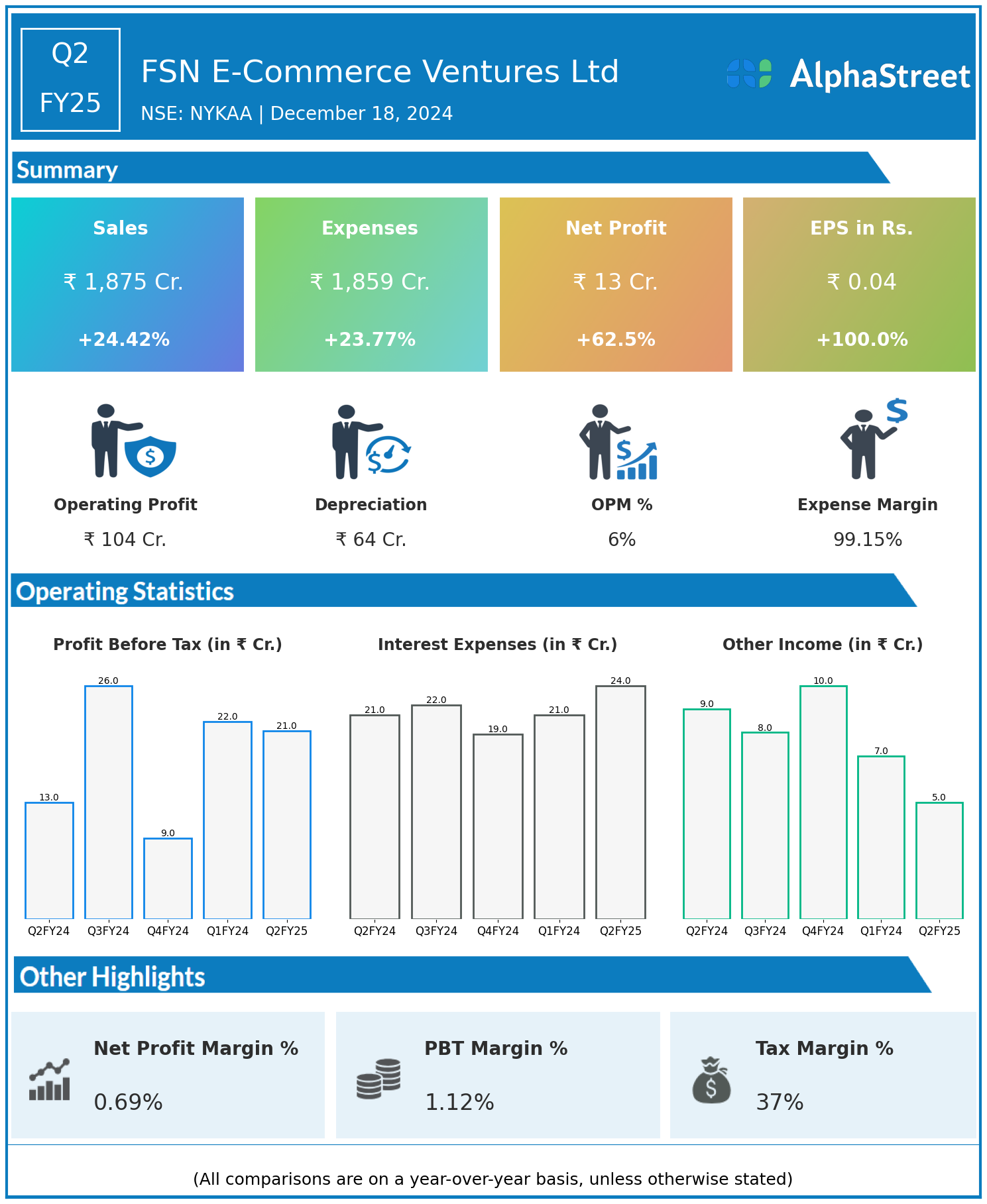

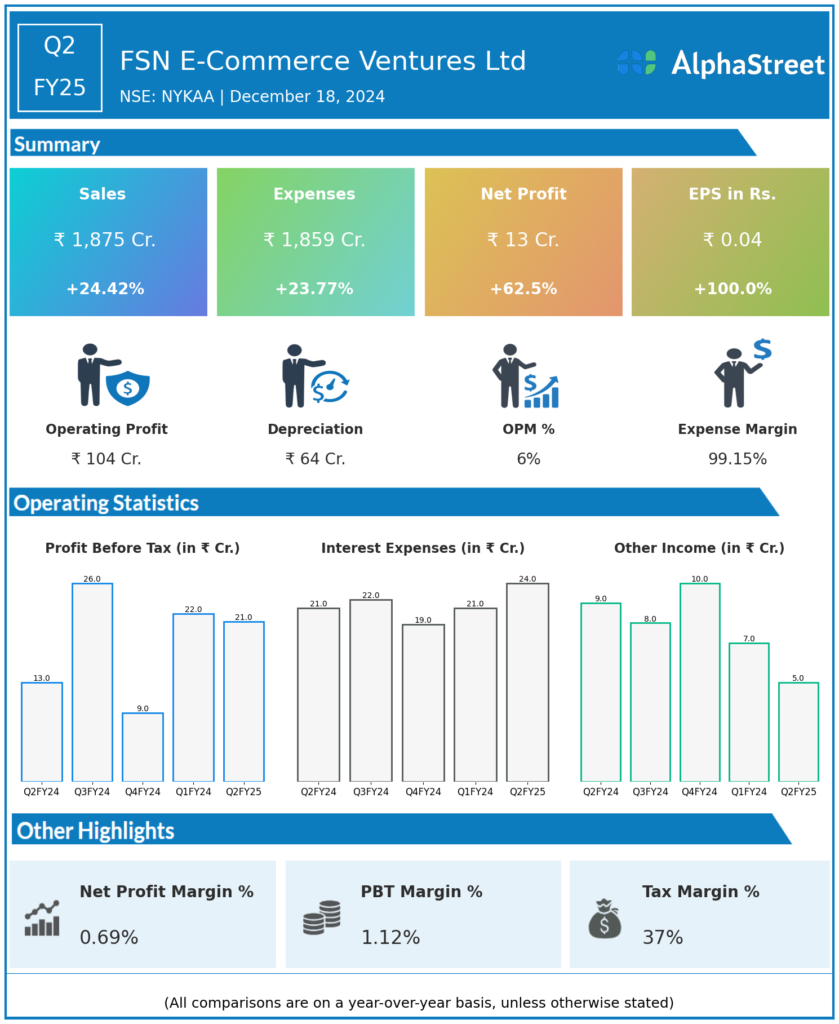

FSN E-Commerce Ventures Ltd reported Revenues for Q2FY25 of ₹1,875.00 Crores up from ₹1,507.00 Crore year on year, a rise of 24.42%.

Total Expenses for Q2FY25 of ₹1,859.00 Crores up from ₹1,502.00 Crores year on year, a rise of 23.77%.

Consolidated Net Profit of ₹13.00 Crores up 62.5% from ₹8.00 Crores in the same quarter of the previous year.

The Earnings per Share is ₹0.04, up 100.00% from ₹0.02 in the same quarter of the previous year.