Asian Paints is the largest home decor company in India. The 80+yyr old company has major brands like Asian Paints, Berger, Apco, etc under its umbrella. The co. is into wall paints, wall coverings, waterproofing, texture painting, wall stickers, mechanized tools, adhesives, modular kitchens, sanitaryware, lightings, soft furnishings, and uPVC windows.

Financial Results:

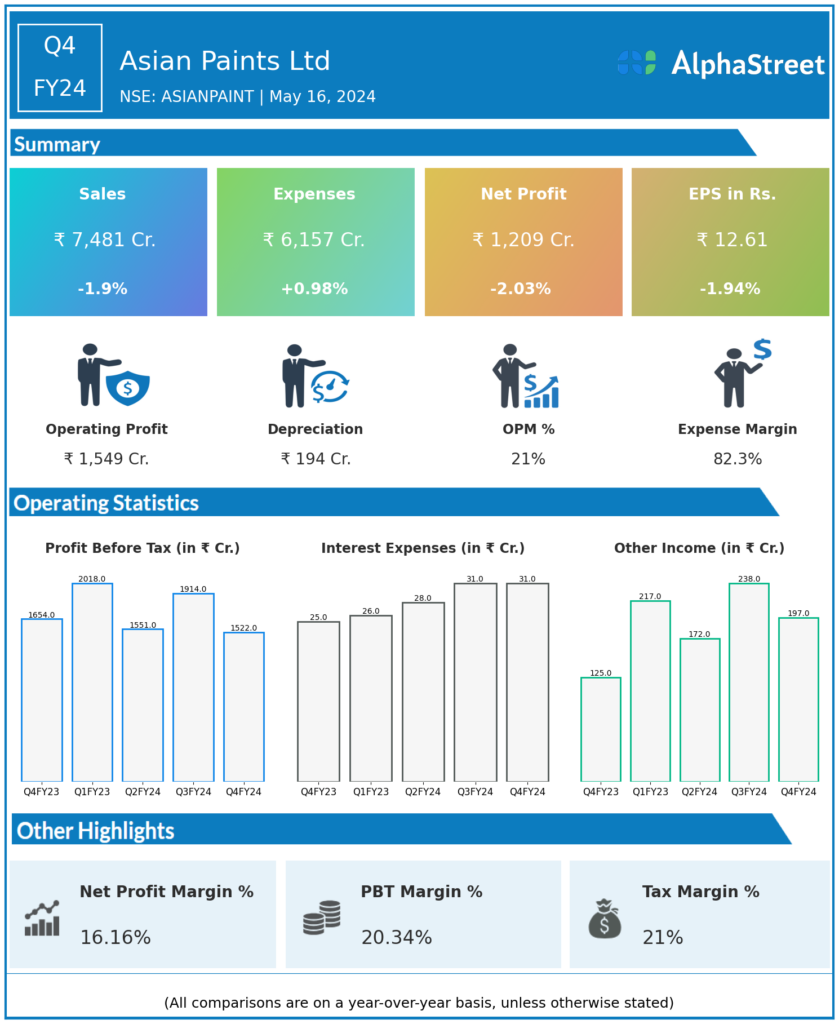

Asian Paints Ltd reported Revenues for Q4FY24 of ₹7,481.00 Crores down from ₹7,626.00 Crore year on year, a fall of 1.9%.

Total Expenses for Q4FY24 of ₹6,157.00 Crores up from ₹6,097.00 Crores year on year, a rise of 0.98%.

Consolidated Net Profit of ₹1,209.00 Crores down 2.03% from ₹1,234.00 Crores in the same quarter of the previous year.

The Earnings per Share is ₹12.61, down 1.94% from ₹12.86 in the same quarter of the previous year.

*It is important to note that the way the results have been accounted for are slightly different than the ones the companies may choose to publish.

*The presented data is automatically generated. It may occasionally generate incorrect information.